Beam Tube

Beam tube is one of the important part of the entire vacuum system. It is a cylindrical structure having 4 km length in each perpendicular direction.

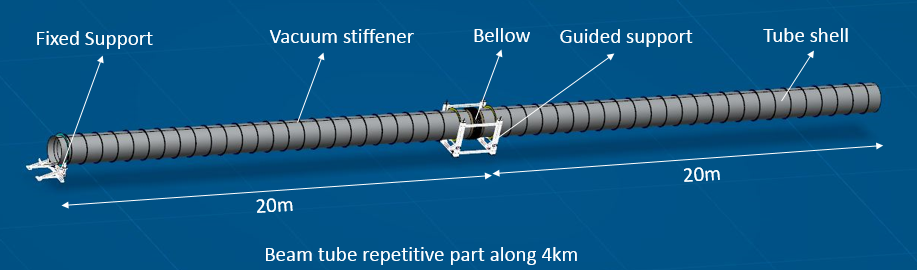

Beam tube 40m repetitive section

The beam tube is kept in ultra-high vacuum so that scattering of laser beam is minimized within the Fabry-Perot cavity. Each beam tube has two (02) numbers of beam tube modules of 2.0 km length each. Each beam tube module will be fabricated from 20 m long beam tube sections of 100 numbers. These beam tube sections will be reinforced with vacuum stiffeners as well as support stiffeners. Vacuum stiffeners are provided at a separation of 750 mm distance throughout the length so that the tube can withstand pressure difference between inside and outside the tube and avoid collapsing. Support stiffeners are provided at 20 m apart to stiffen and assemble the support structure for the beam tube.

Beam Tube Support

Three types of support structures are used. They are (a) fixed supports, (b) guided supports and (c) termination supports are also attached with the support stiffeners as shown in fig (b)

Different types of support structures that will be used to anchor the beam tubes.

Different types of support structures that will be used to anchor the beam tubes.

(a) Fixed support (b) Guided support and (c) Termination support

BSC and HAM

Basic Symmetric Chambers (BSC) are used to support core optical components while Horizontal Access Module (HAM) are used to house auxiliary optics. All major optical components are housed in these two chambers. Both BSC and HAM chambers are provided with demountable cover flanges so that the servicing of the optical components could be carried out whenever needed. These chambers contain seismic isolators and alignment mechanism which support the optical elements and have internal attachment brackets. These brackets will be used to support lightweight optical components. The seals on these cover flanges shall be designed as double O-rings with a pumped annulus to reduce the gas load due to the permeability of Viton. A clean air vent and purge system shall be provided to break vacuum and maintain cleanliness of the optical components whenever a chamber is open.

3D view of BSC